Sistema de visión FH

Mayor velocidad de funcionamiento, cámaras para cada aplicación

Esta gama incluye las ventajas de una cámara inteligente y un potente sistema de visión en una única plataforma. La incomparable claridad de imagen que aporta una cámara inteligente permite una configuración sencilla, una instalación rápida y un rendimiento óptico mejorado.

- Los componentes de alto rendimiento ofrecen unas prestaciones excepcionales para satisfacer los requisitos más exigentes

- Los algoritmos y las herramientas de visión inteligentes hacen que todas las aplicaciones sean robustas y fiables a cualquier velocidad

- La gama de cámaras actual le permite elegir el hardware más adecuado para cada aplicación; el mejor rendimiento al mejor precio

- La IA reproduce la sensibilidad y la experiencia humanas

- Fácil integración con software para una automatización flexible

- Procesamiento en color real (16 millones de colores)*

- Comunicación mediante EtherNet/IP y TCP/IP*

¿Necesita ayuda?

Estamos aquí para ayudarle. Póngase en contacto con nosotros y nuestros especialistas le ayudarán a encontrar la mejor solución para su negocio.

Contacten conmigo Sistema de visión FH

Gracias por enviarnos su solicitud. Le responderemos lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadPresupuesto para Sistema de visión FH

A través de este formulario puede solicitar cotización del producto escogido. Por favor, cumplimente todos los campos marcados con *. Sus datos personales serán tratados con la máxima confidencialidad.

Gracias por la cotización solicitada. Le enviaremos la información solicitada lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadCaracterísticas

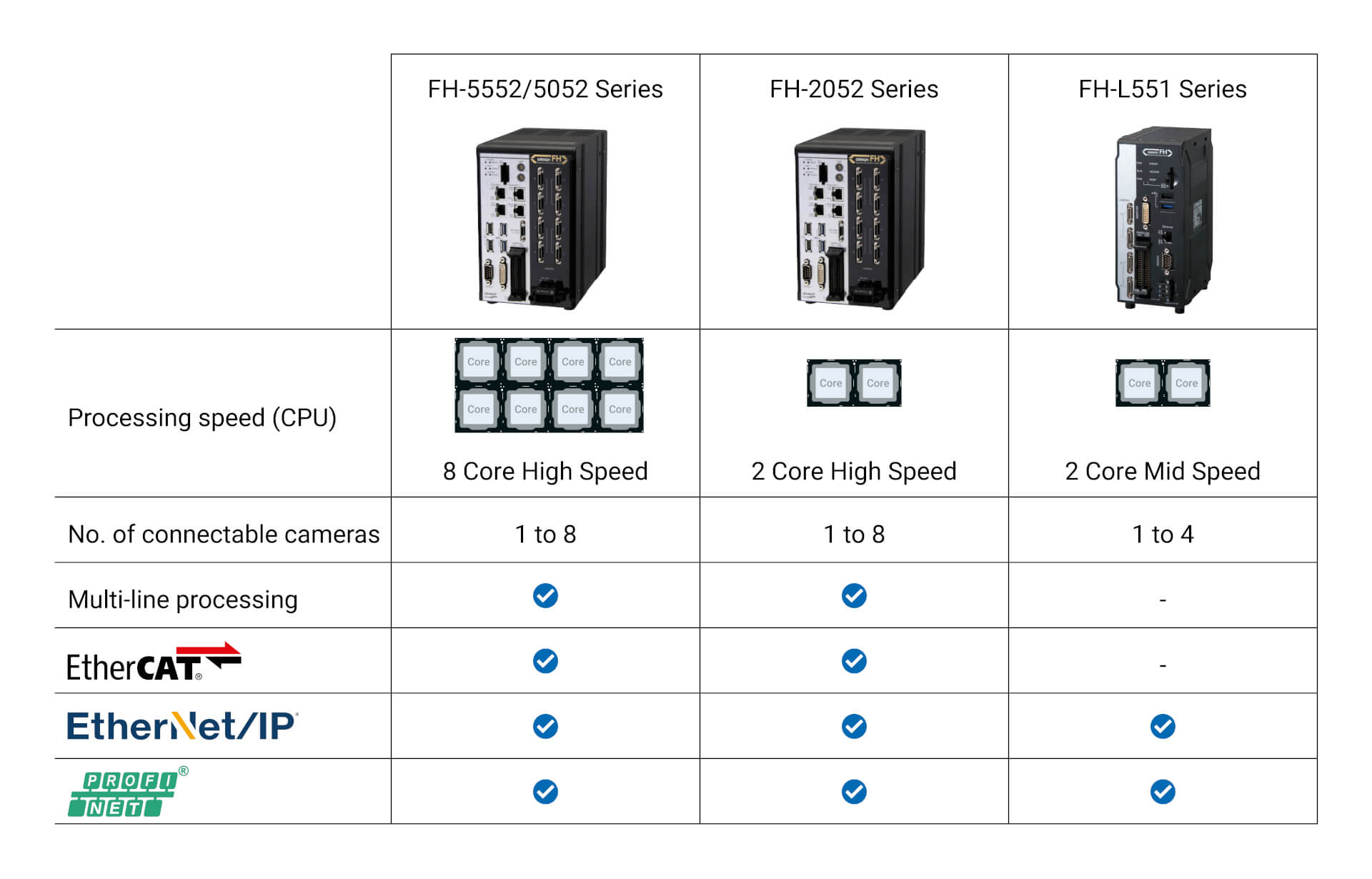

Controladores potentes para tareas rápidas y precisas de inspección y medición

Seleccione los controladores que mejor se adapten a sus requisitos. Todos los controladores pueden compartir los mismos valores, lo que aporta flexibilidad al diseño de la máquina.

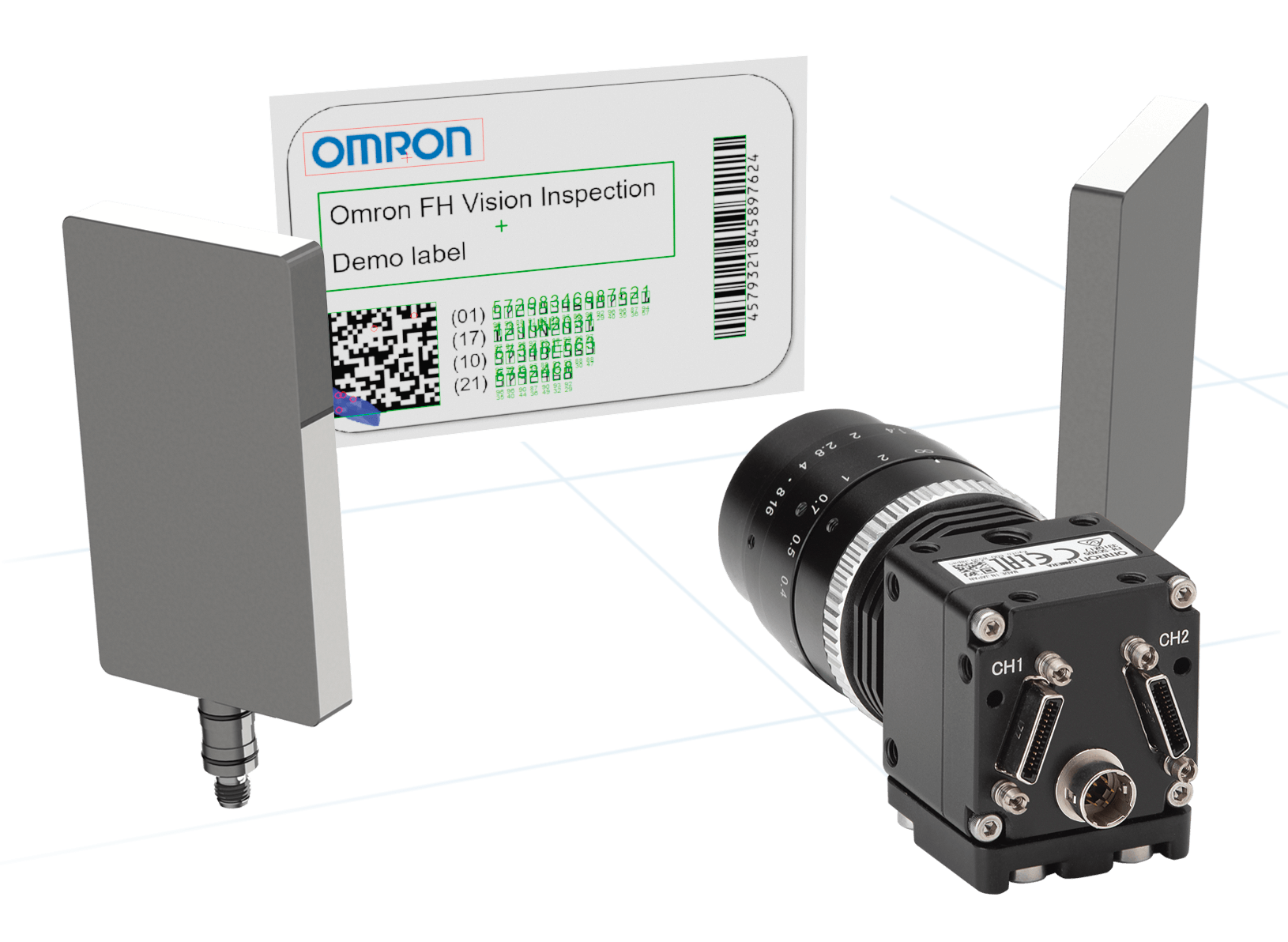

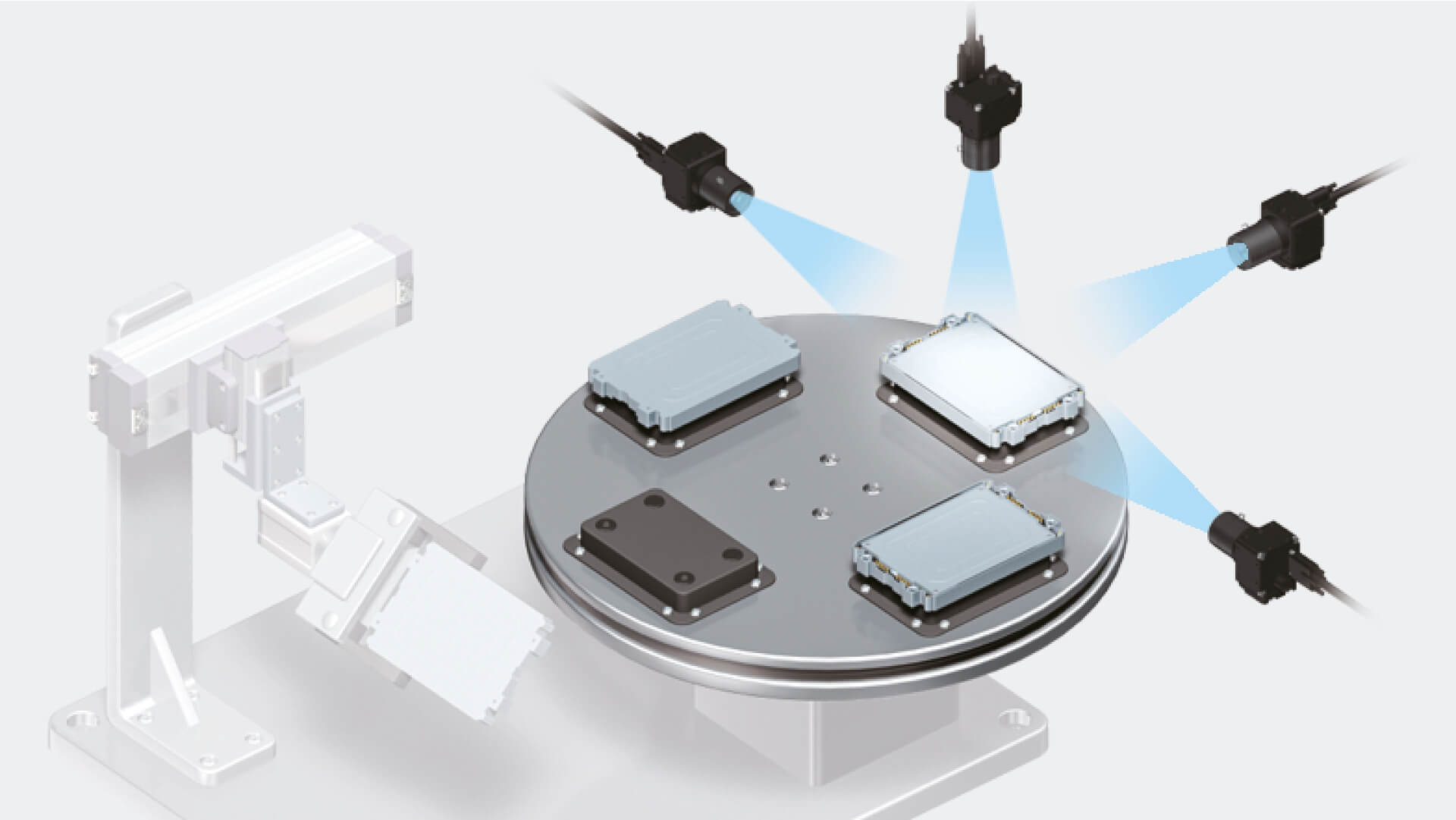

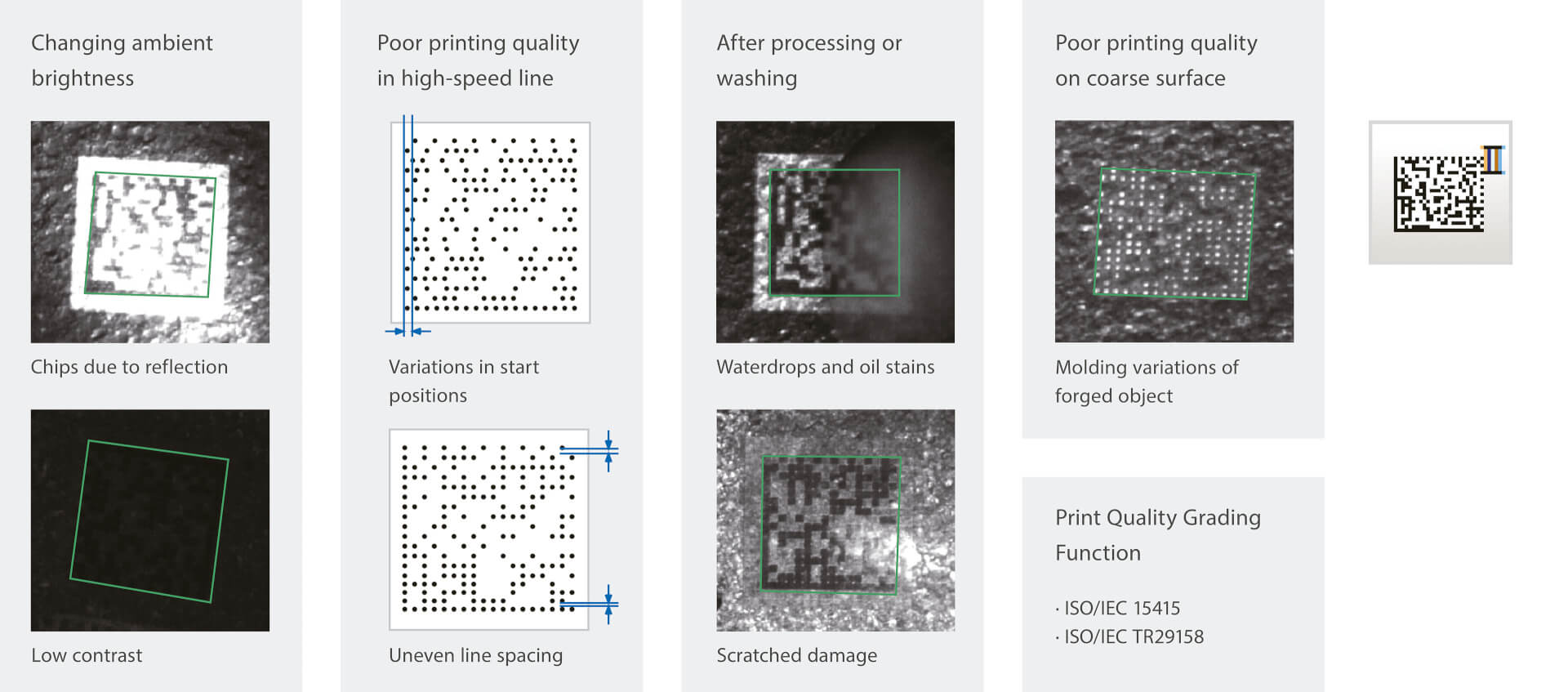

Gama completa de cámaras de alta velocidad y alta resolución

Las cámaras FH están diseñadas para su uso en todo tipo de aplicaciones de reconocimiento de objetos, posicionamiento u orientación, lectura de códigos y medición; además, este tipo de cámara compacta y sistema de control se integra fácilmente en cualquier máquina o robot. El sistema está especialmente capacitado para proporcionar un rendimiento más rápido y preciso, con el fin de ofrecer más eficacia, menos costes y mucho más.

Detección ampliada con SWIR y cámaras polarizadas

OMRON ha mejorado significativamente sus capacidades de detección de imágenes al ampliar su gama de cámaras. Ahora ofrecemos dos resoluciones de cámara SWIR y dos cámaras de resolución polarizadas. Estas incorporaciones mejoran considerablemente el rango de detección y la versatilidad de la gama FH.

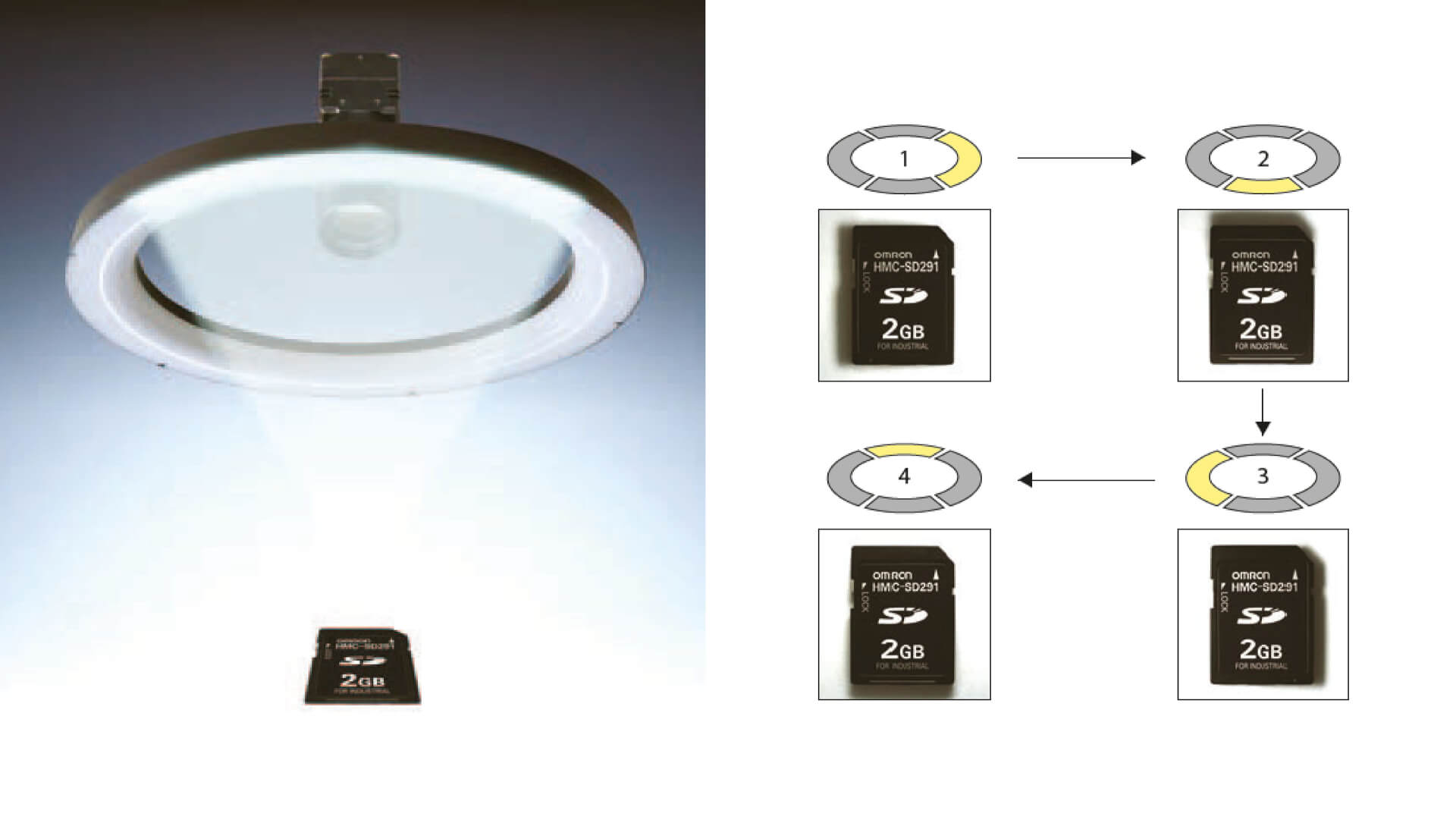

Imágenes estereométricas avanzadas

La luz estéreo fotométrica FH se puede utilizar con cámaras estándar o de alta resolución de hasta 20,4 Mpix. para detectar abolladuras y daños en la superficie con alta precisión. Se encienden cuatro luces por turnos y se analizan las variaciones de brillo. Los caracteres impresos con poca variación en el brillo, incluso en diferentes direcciones de iluminación, se extraen como textura, y una abolladura con una gran variación en el brillo se extrae como forma.

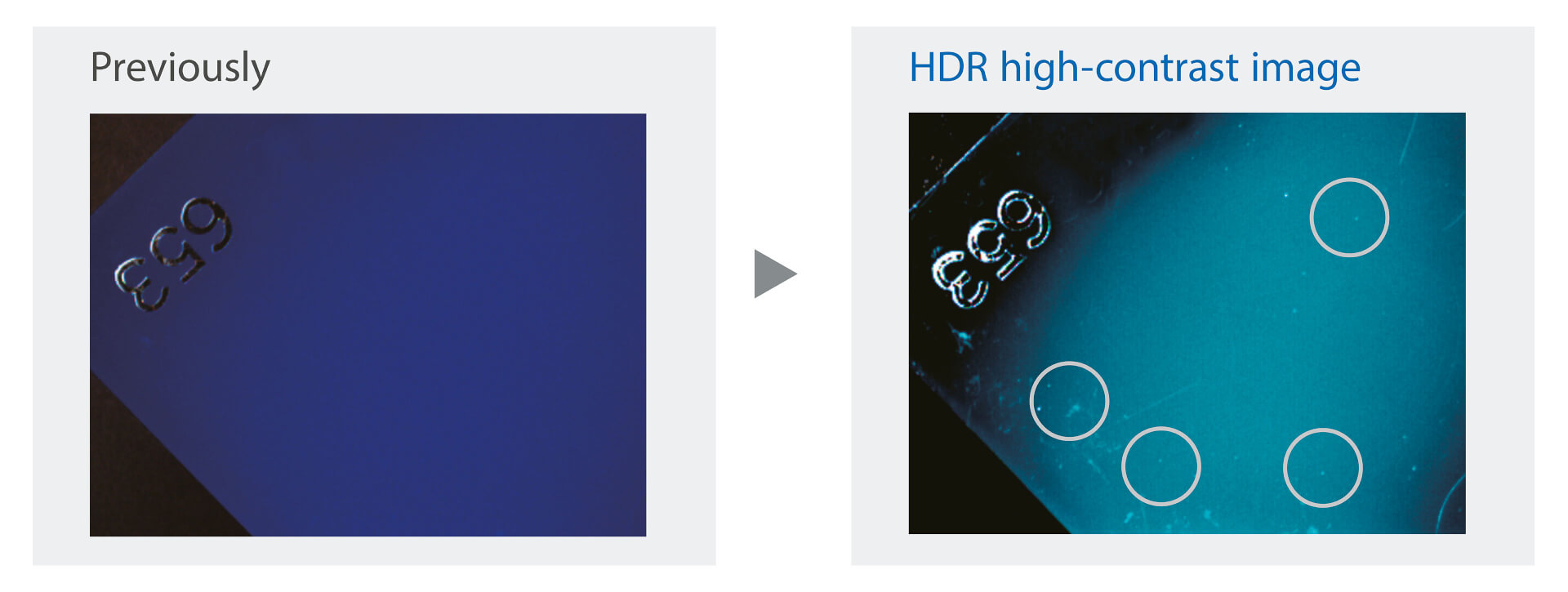

Imagen HDR

El formato HDR ayuda a crear imágenes optimizadas en condiciones ambientales variables. Una vez que haya especificado el área óptima para capturar en la imagen, la serie FH ajusta automáticamente la velocidad de obturación mientras captura imágenes y las combina.

Herramientas integrales de visión basadas en reglas

Las herramientas de visión basadas en reglas FH de OMRON marcan el camino en la automatización industrial moderna y ofrecen soluciones de vanguardia para tareas de control de calidad, inspección y optimización de procesos. Mediante algoritmos avanzados y tecnología de adquisición de imágenes de alta precisión, estas herramientas ejecutan tareas complejas con una precisión y fiabilidad excepcionales. Diseñadas para facilitar el uso, las herramientas de visión de OMRON garantizan una integración perfecta con los sistemas existentes y requieren un tiempo de configuración mínimo.

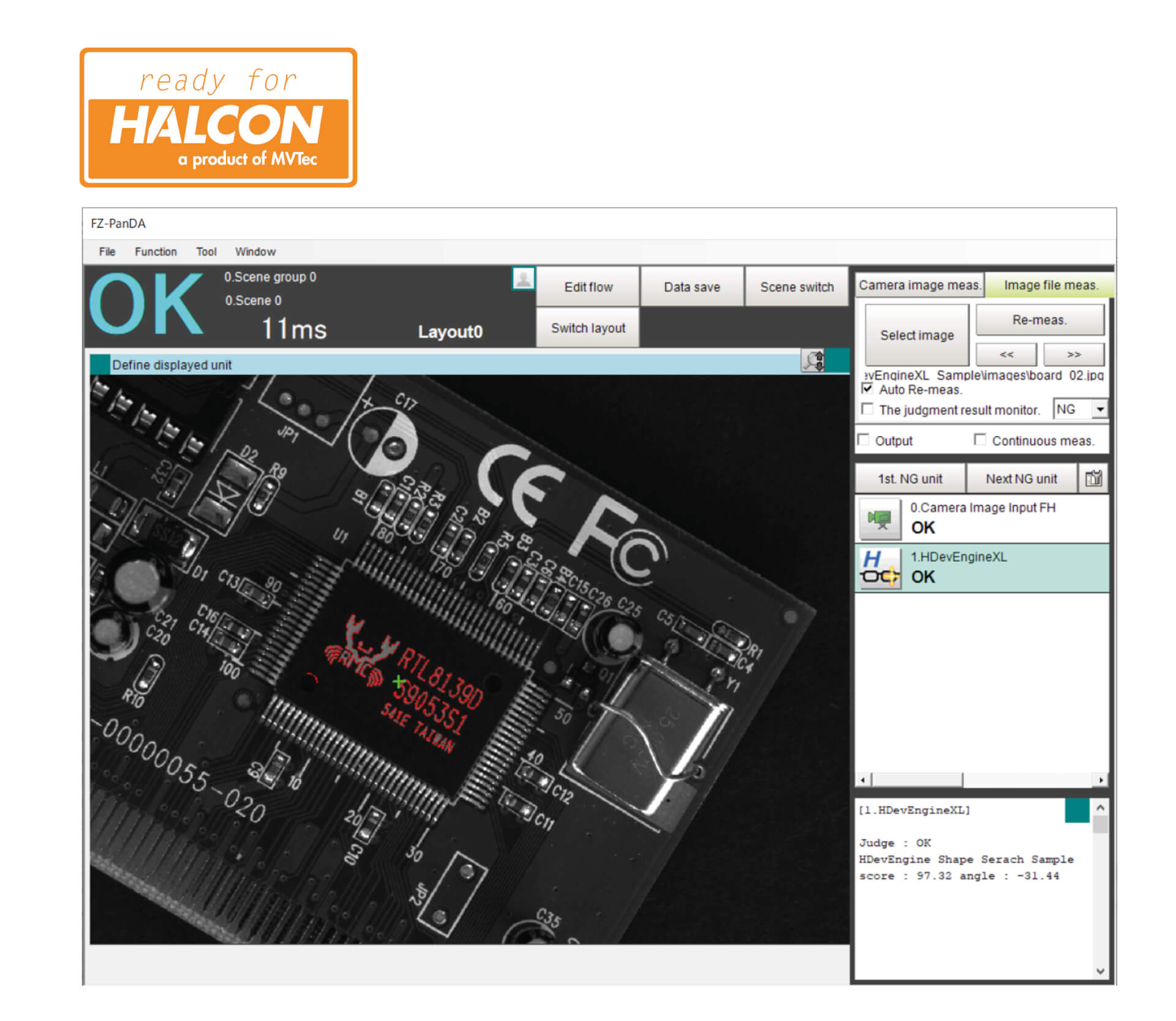

FH abierto

Además de los algoritmos de visión patentados de OMRON, el controlador de visión FH es compatible con los algoritmos de visión desarrollados con el software Halcon HDevelop de MVTec. Esta flexibilidad permite a los fabricantes seleccionar la mejor opción algorítmica para los requisitos específicos de su aplicación, lo que garantiza un rendimiento y una eficiencia óptimos en sus soluciones de visión.

AI Features

Procesamiento basado en reglas e IA

Hardware estable y fiable:

El hardware de visión de OMRON se ha diseñado para soportar los entornos industriales más exigentes y ofrecer un rendimiento constante incluso en las condiciones más difíciles. Su robusto diseño garantiza la fiabilidad a largo plazo, lo que reduce el tiempo de inactividad y los esfuerzos de mantenimiento.

Integración perfecta de herramientas de inspección con IA:

Mejore su sistema de inspección tradicional basado en reglas con capacidades de IA. La serie FH de OMRON le permite añadir herramientas de inspección con IA avanzadas a su configuración existente, combinando la precisión de la inspección basada en reglas con la adaptabilidad del análisis basado en IA.

Modelo de licencia permanente económico:

Ya no tendrá que invertir su tiempo en la elaboración de presupuestos anuales y la renovación de contratos. La serie FH de OMRON ofrece un modelo de licencia permanente que le proporciona acceso a largo plazo a tecnología de inspección de vanguardia sin cuotas de suscripción recurrentes.

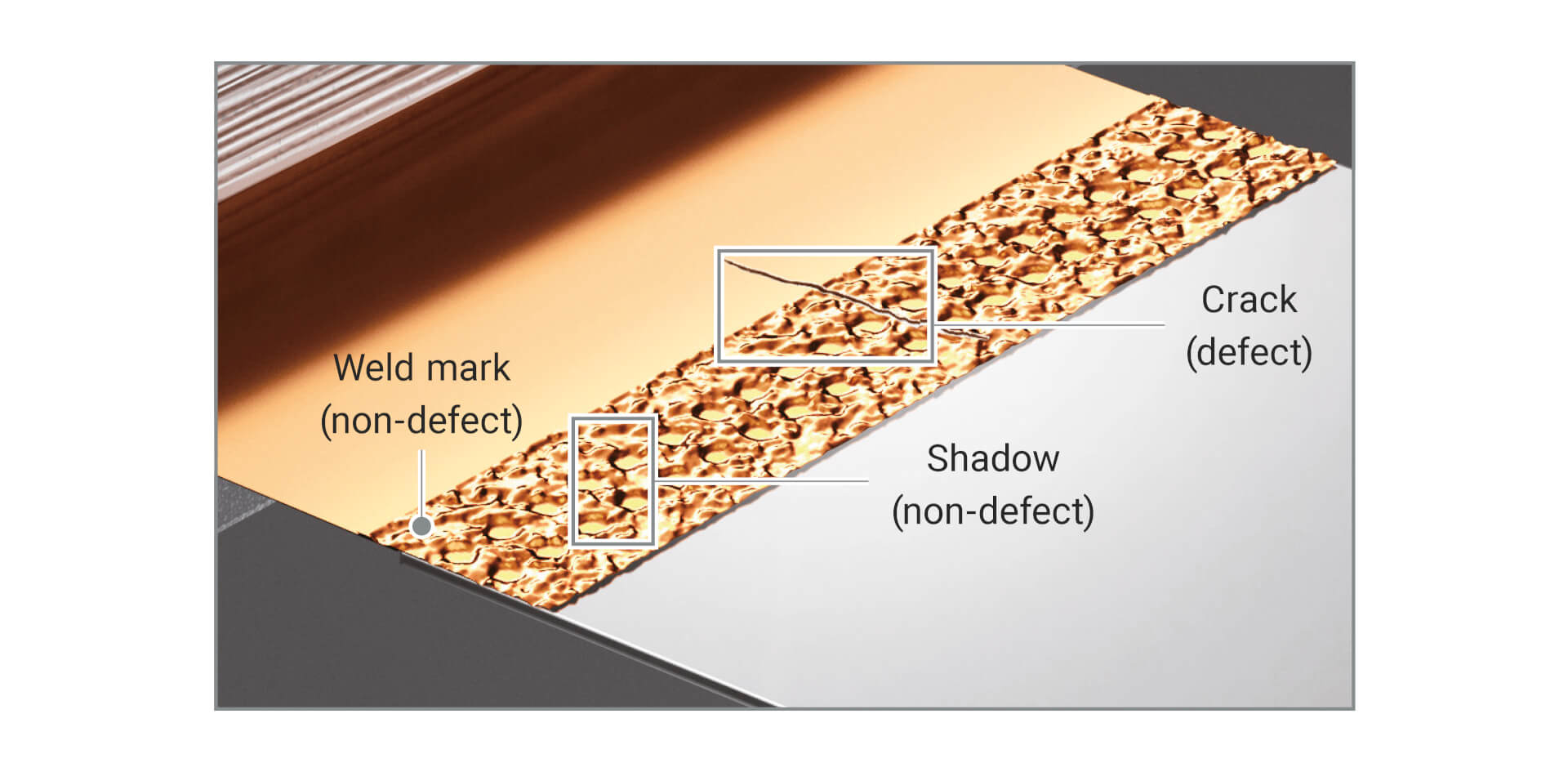

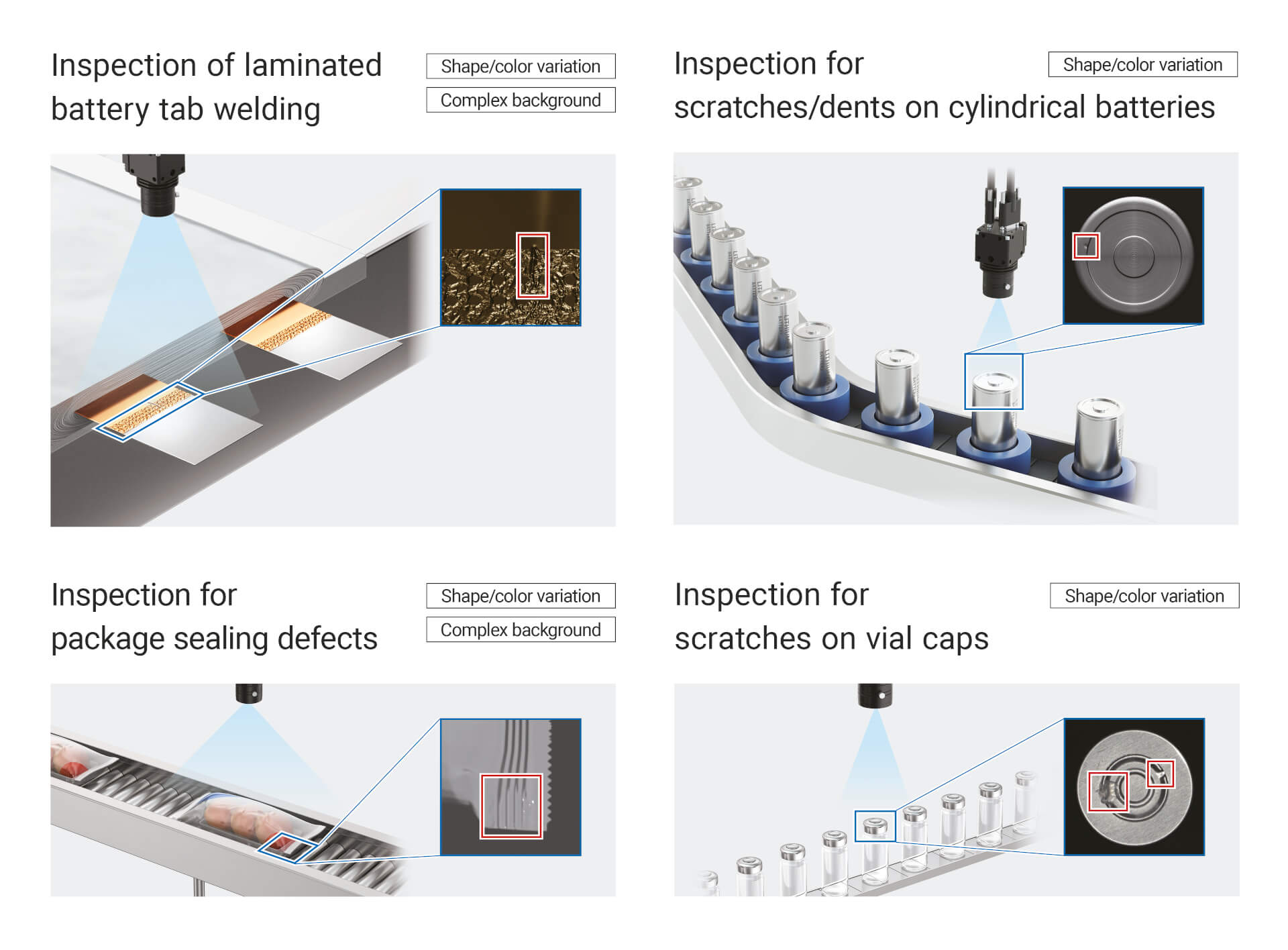

Inspección de defectos con IA

El algoritmo de inspección de defectos con IA de OMRON supone un cambio radical en el control de calidad. Utiliza inteligencia artificial avanzada para detectar defectos de forma precisa y reducir al mínimo los falsos positivos. Este sistema, diseñado para afrontar retos comunes como las variaciones de forma, color y brillo, así como los fondos complicados, permite inspecciones en tiempo real en la planta más precisas y eficientes. Lo que realmente lo diferencia son sus capacidades de autoaprendizaje y su sencilla configuración en tres pasos, que convierte la compleja detección de defectos en una tarea sencilla y fiable. Tanto si trabaja en el sector de la automoción, electrónico, alimentario o farmacéutico, las soluciones de visión inteligente de OMRON le ofrecen la precisión y eficiencia que necesita.

Proceso de configuración en 3 pasos

- Organización de imágenes: clasifique sus imágenes en productos "no defectuosos" y "defectuosos"

- Anotación: marque los defectos como si se los estuviera indicando a otra persona.

- Aprendizaje: simplemente inicie el proceso de autoaprendizaje y la configuración se completará en cuestión de minutos.

Elimine la sobredetección

- Algoritmo de IA avanzado: reduce los falsos positivos de las variaciones de forma, color y brillo.

- Tecnología de autoaprendizaje: entrena rápidamente el modelo con un número mínimo de imágenes, garantizando resultados fiables y reproducibles.

- Procesamiento con reconocimiento de contexto: detecta únicamente defectos significativos, ignorando el ruido de fondo irrelevante

Solución fiable en diversos sectores

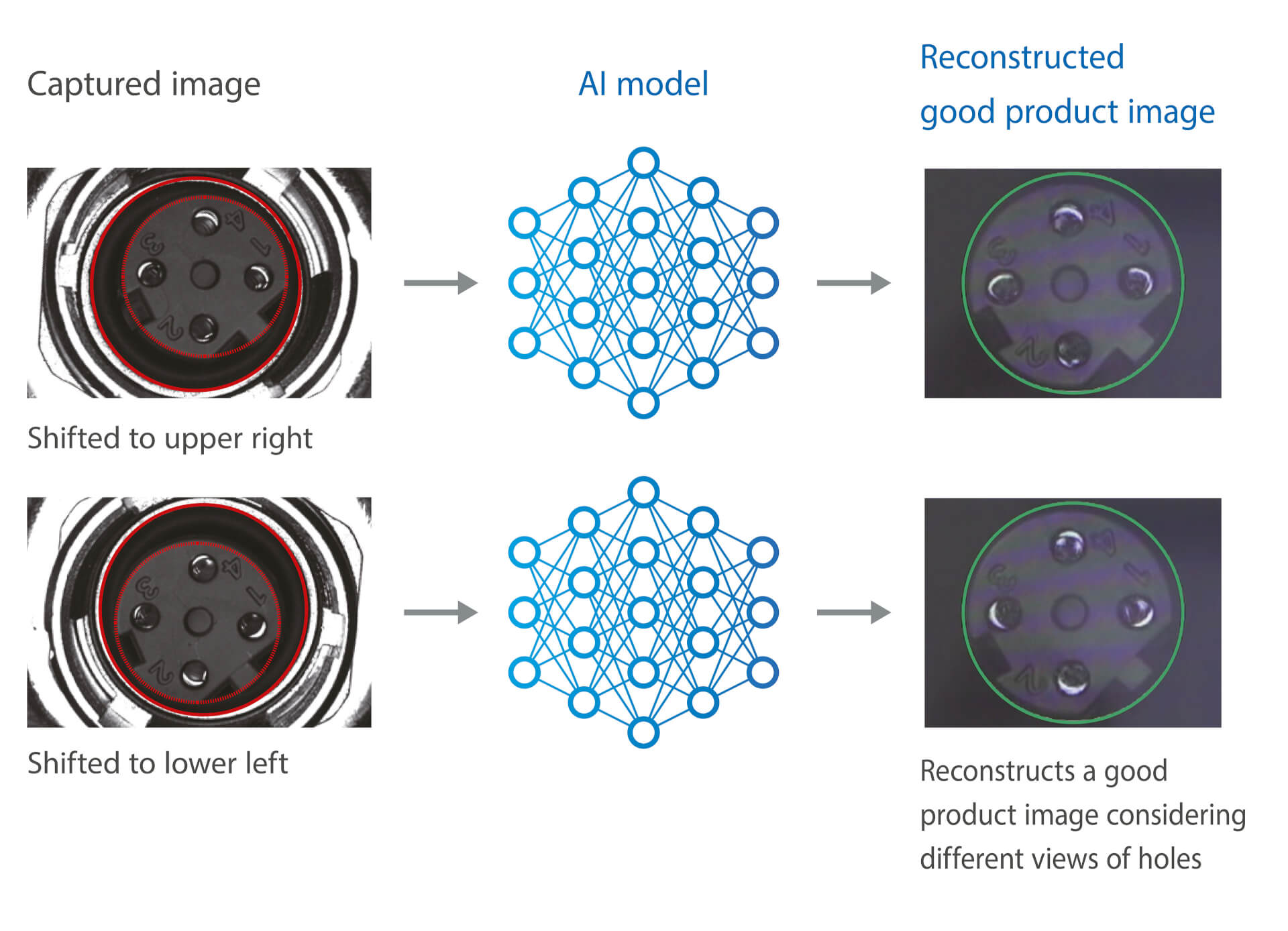

Reconocimiento preciso de IA

El reconocimiento preciso de IA identifica una característica que no está incluida en los productos correctos como un defecto. La IA aprende imágenes de productos correctos con sus variaciones y genera un modelo de IA. Cada vez que se realiza una inspección, la IA reconstruye un modelo que supone que es un producto correcto. La IA extrae entonces una diferencia entre la imagen reconstruida del producto correcto y una imagen capturada para identificar un defecto, lo que reduce la incidencia de la sobredetección.

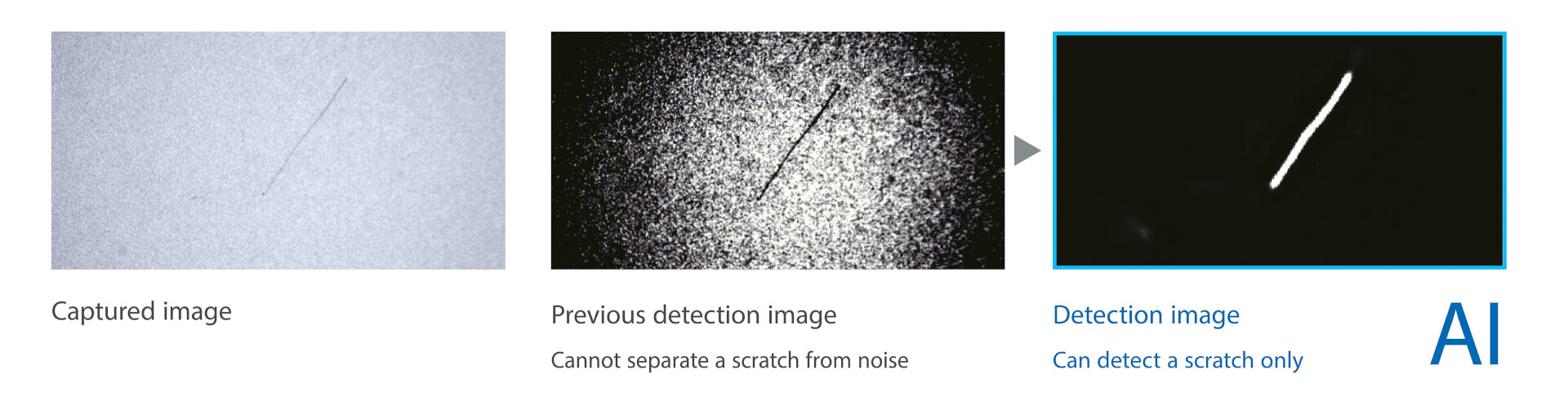

Defecto de arañazos de IA

Las funciones más recientes del sistema de visión FH incluyen un filtro de imágenes basado en IA que reproduce la técnica que utilizan los inspectores cualificados para identificar un defecto en cualquier fondo del producto. Los arañazos y las imperfecciones que antes eran difíciles de capturar ahora se pueden identificar incluso sin el uso de muestras o ajustes.

Aplicaciones

Mejora de la detección con cámaras de exploración lineal

Las cámaras de exploración lineal tienen una ventaja significativa sobre las cámaras de exploración de área en lo que respecta a objetos grandes, cilíndricos o en movimiento continuo. La serie FH admite la conexión de hasta 4 cámaras de exploración lineal con una resolución de 2K a 8K.

Soluciones optimizadas con imágenes de exploración lineal

Las líneas de producción de movimiento rápido, los objetos curvos o cilíndricos, o las aplicaciones con espacio limitado son ideales para la adquisición de imágenes de exploración lineal. Entre las aplicaciones más habituales se incluyen:

- Etiqueta de inspección para productos cilíndricos que requieren inspección.

- Inspecciones continuas en aplicaciones pick & place o aplicaciones de recuento.

- Inspección de defectos/superficies de baterías de vehículos eléctricos que requieren una inspección de la superficie completa de la pieza.

Sistema de visión preparado conforme a la norma 21 CFR parte 11 y GMP

El sistema de visión FH se puede actualizar para que sea compatible con la norma 21 CFR parte 11 y GMP, lo que permite a los fabricantes de dispositivos médicos, farmacéuticos y científicos instalar sistemas de visión en sus líneas de producción para cumplir con estas normativas.

Características del software

- Informe de seguimiento de auditoría

- Visor de seguimiento de auditoría

- Seguridad de contraseña mejorada

- Archivos cifrados

- Control de acceso de usuarios

- Preparación de inicio de sesión único

- Integración HMI

Decodificación de marca de agua digital Digimarc

Decodificación incomparable en envases cilíndricos y flexibles

Inspección del aspecto de las pilas recargables

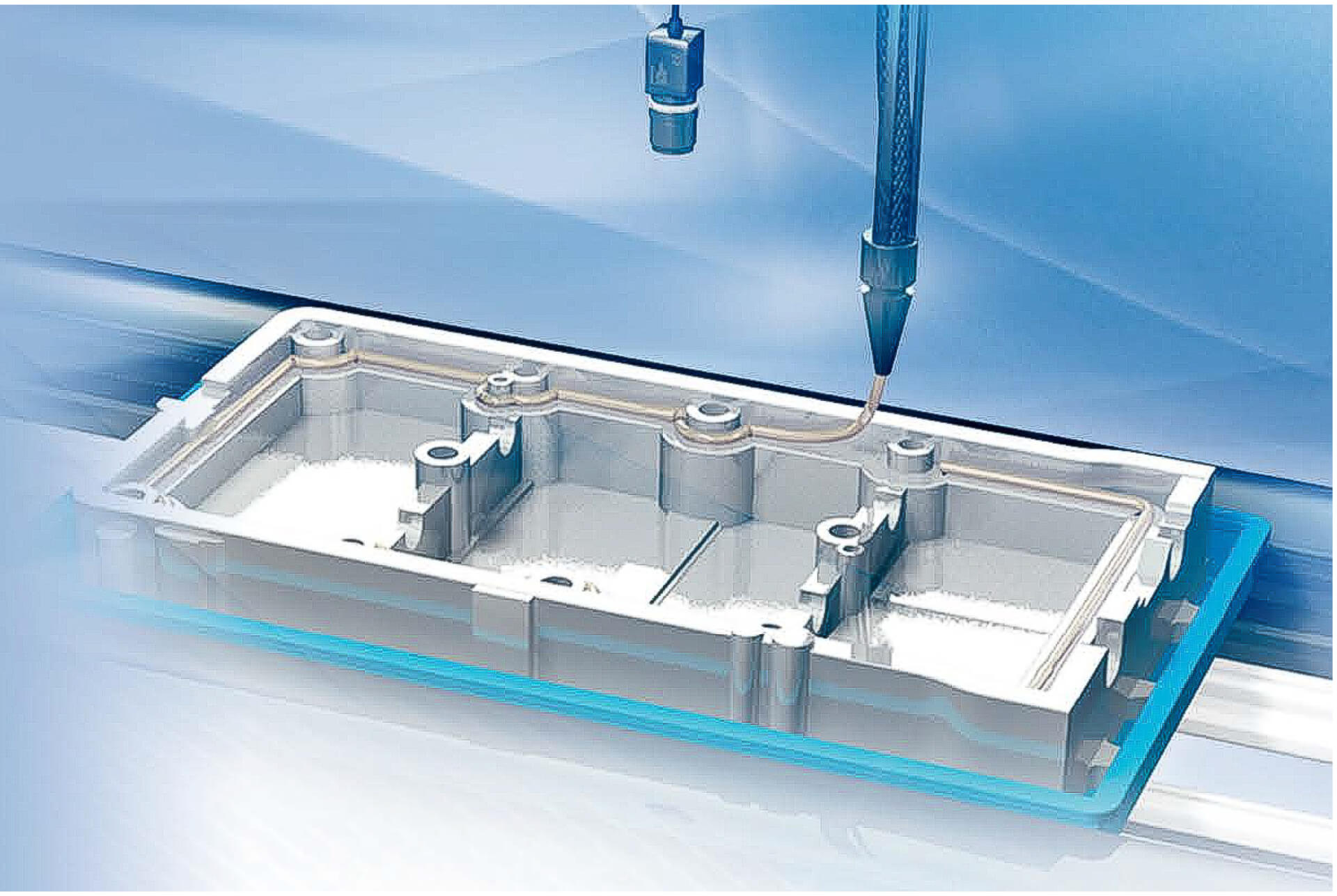

Inspección de cordones de pegamento

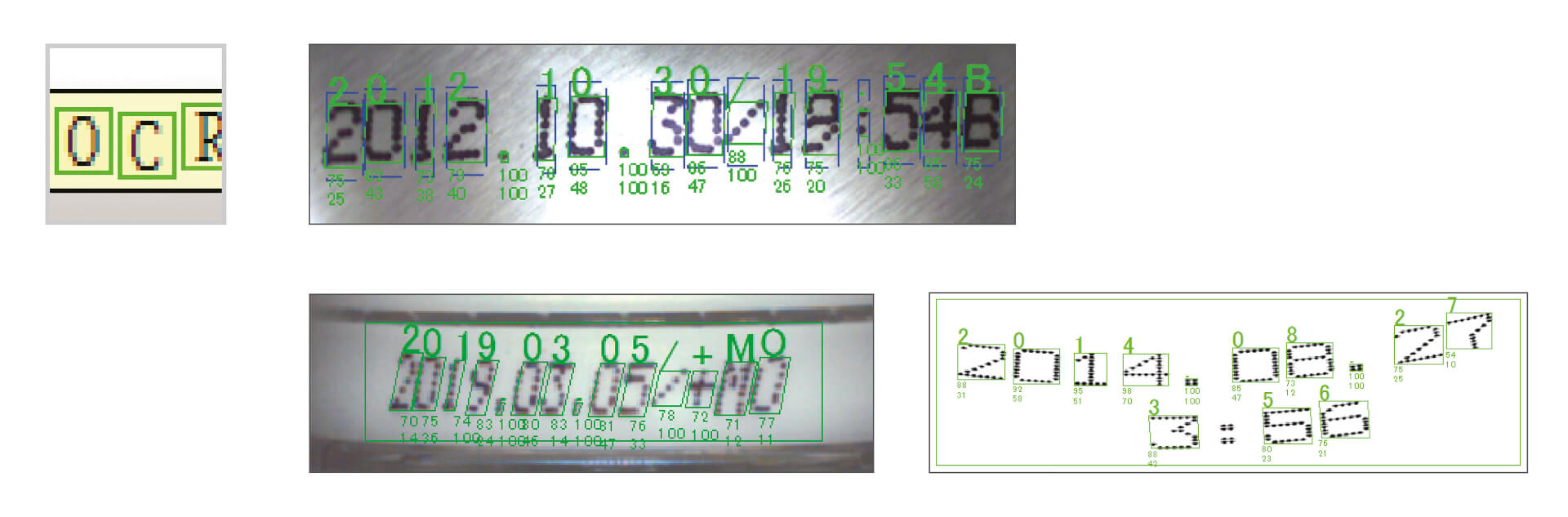

Lectura fiable de caracteres de difícil lectura

Lens Selector

Vídeos

-

FH Vision System from OMRON: AI defect inspection for chips on glass bottles

Stable detection of just the defects, even with workpiece gloss variations.

03:07

FH Vision System from OMRON: AI defect inspection for chips on glass bottles

Stable detection of just the defects, even with workpiece gloss variations.

-

FH Vision System: AI defect inspection of laminated battery tab welding

Stable detection of just the defects, even with workpiece gloss variations.

02:44

FH Vision System: AI defect inspection of laminated battery tab welding

Stable detection of just the defects, even with workpiece gloss variations.

-

FH Vision System from OMRON: AI defect inspection of stator powder coating

Stable detection of just the defects, even with workpiece gloss variations.

03:08

FH Vision System from OMRON: AI defect inspection of stator powder coating

Stable detection of just the defects, even with workpiece gloss variations.

-

3 Step Easy Configuration of AI Defect Inspection FH Vision System from OMRON

OMRON has created the AI defect inspection feature that is easy to use for anyone.

02:47

3 Step Easy Configuration of AI Defect Inspection FH Vision System from OMRON

OMRON has created the AI defect inspection feature that is easy to use for anyone.Especificaciones y modelos disponibles

| Producto | Performance | Processor family | Operating system | Memory | AI Scratch detection filter | AI FineMatching | Number of cameras | Integrated monitor | Communication port(s) | Output type | Application | Descripción | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (ECC) | No | No | 4 | No | EtherCAT Slave, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next Generation de alta velocidad / alto rendimiento / almacenamiento ampliado, controlador de 8 núcleos, NPN/PNP, 4 cámaras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 2 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH-Lite controller, standard grade, box type, 2 camera, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 4 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Counting, Defect inspection, Measurement inspection, OCR / OCV | FH-Lite controller, standard grade, box type, 4 camera, , W10 IoT Enterprise LTSC 2019 64bit |

|

Sistema de Visión FH industrial con detección de defectos mediante Inteligencia Artificial

El sistema de procesamiento de imágenes identifica defectos sutiles con una sensibilidad similar a la de los seres humanos para conseguir tasas de detección de defectos más elevadas.

Estamos aquí ayudarle

¿Tiene alguna pregunta? Nuestros especialistas están disponibles para ayudarle en cada paso.

Contacten conmigo Sistema de visión FH

Gracias por enviarnos su solicitud. Le responderemos lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadPresupuesto para Sistema de visión FH

A través de este formulario puede solicitar cotización del producto escogido. Por favor, cumplimente todos los campos marcados con *. Sus datos personales serán tratados con la máxima confidencialidad.

Gracias por la cotización solicitada. Le enviaremos la información solicitada lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadDescargas

Continúe e inicie sesión, o bien, regístrese al contenido de esta página

Continúe e inicie sesión, o bien, regístrese al contenido de esta página

Continúe e inicie sesión, o bien, regístrese al contenido de esta página

Productos relacionados

¿Necesita ayuda?

Estamos aquí para ayudarle. Póngase en contacto con nosotros y nuestros especialistas le ayudarán a encontrar la mejor solución para su negocio.

Contacten conmigo Sistema de visión FH

Gracias por enviarnos su solicitud. Le responderemos lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadPresupuesto para Sistema de visión FH

A través de este formulario puede solicitar cotización del producto escogido. Por favor, cumplimente todos los campos marcados con *. Sus datos personales serán tratados con la máxima confidencialidad.

Gracias por la cotización solicitada. Le enviaremos la información solicitada lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

Download