E5_D/H

Controladores de nueva generación

E5_D/H es la nueva generación de controladores diseñados para conseguir un control de temperatura óptimo y automático sin intervención humana. De hecho, a partir de ahora todos los ajustes típicos que los expertos realizan en el campo se automatizan gracias a la inteligencia artificial (IA).

- La "tecnología de control adaptativo" detecta automáticamente cambios en el proceso bajo control y adapta el PID de acuerdo a estos cambios

- Funciones especializadas para máquinas de envasado y extrusoras refrigeradas por agua

- Display LCD con caracteres blancos, de gran tamaño y alto contraste, visible a gran distancia y desde diferentes ángulos

- Función de cambio del banco (grupo PID), para realizar cambios rápidos en la configuración del dispositivo (solo E5_D-H)

- 5 funciones de sobrealimentación previa para suprimir fluctuaciones de temperatura predecibles (solo E5_D-H)

Especificaciones y modelos disponibles

| Producto | Size | Functions | Number of control loops | Temperature input type | Linear analog input type | Temperature range | Features | Number of event inputs | Number of alarm outputs | Supply voltage AC | Supply voltage DC | Control output | Communication port(s) | Terminal type | Descripción | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Linear current | Serial RS-485 | Push-in | Controlador de Temperatura Digital Avanzado, 48 x 48 mm, Salida de Corriente Lineal, 2 Salidas de Alarma, 100-240 V, Push-in, -200-2300 °C, 2 Entradas de Evento, Serie RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output,, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX, RS-485, Ht. Burnout SSR fail., 100 to 240 VAC |

|

||

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Controlador de Temperatura Digital Avanzado, 48 x 96 mm, Salida de Pulso de Tensión, Salida de Relé, 100-240 V, Push-in, -200-2300 °C, 4 entradas de eventos, Alarma HB/HS para calentadores trifásicos, Salida de transferencia, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Relay | Serial RS-485 | Push-in | Controlador de Temperatura Digital Avanzado, 48 x 96 mm, 2 Salidas de Relé, 4 Salidas de Alarma, 100-240 V, Push-in, -200-2300 °C, 4 Entradas de Evento, Serie RS-485, Alarma HB/HS para calentadores trifásicos, Salida de transferencia, Remote SP |

|

¿Necesita ayuda?

Estamos aquí para ayudarle. Póngase en contacto con nosotros y nuestros especialistas le ayudarán a encontrar la mejor solución para su negocio.

Contacten conmigo E5_D/H

Gracias por enviarnos su solicitud. Le responderemos lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadPresupuesto para E5_D/H

A través de este formulario puede solicitar cotización del producto escogido. Por favor, cumplimente todos los campos marcados con *. Sus datos personales serán tratados con la máxima confidencialidad.

Gracias por la cotización solicitada. Le enviaremos la información solicitada lo antes posible.

Tenemos dificultades técnicas. Su formulario no ha sido enviado. Porfavor, acepte nuestras disculpas e inténtelo de nuevo más tarde.\ Detalle: [details]

DownloadCaracterísticas

Algoritmo de control adaptativo

-

E5_D Temperature contoller: Adaptive control algorithm

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the E5_D Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

01:26

Con los controladores de temperatura estándar, no solo se necesita mucho tiempo para definir los ajustes del PID en el arranque inicial, sino que también es muy complicado realizar los ajustes óptimos si no se tiene experiencia en este área. Por eso, Omron ha desarrollado la serie E5_D con "tecnología de control adaptativo". Este sistema detecta automáticamente los cambios en el proceso que está siendo controlado y adapta el PID en base a ello.

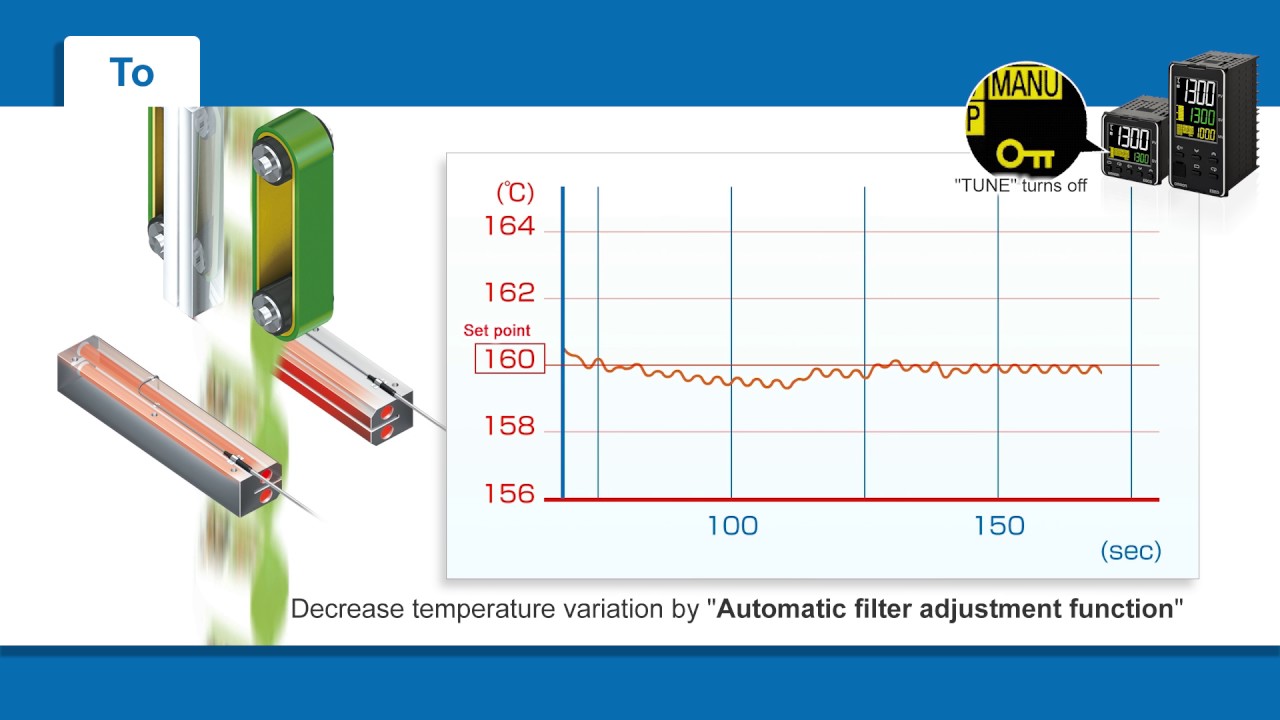

Control perfecto de la temperatura de sellado en máquinas de packaging

-

E5_D TC: Perfect sealing temperature control for packaging machines (1)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:25

En una máquina de sellado convencional, los sensores de temperatura suelen estar ubicados lejos de la superficie de la barra de termosellado. Esto provoca diferencias entre la temperatura de la superficie de sellado y la temperatura real que se está controlando. Esta diferencia de temperatura y los fallos resultantes aumentan a medida que sube la velocidad y también con materiales de packaging de menor grosor o cambios en la temperatura ambiente.

Gracias a la serie E5_D este problema se resuelve si se tienen en cuenta las siguientes indicaciones:

- instalación del sensor más próximo a la superficie de sellado, gracias a modelos especiales de sensores de temperatura que tienen una detección más rápida

-

E5_D: Perfect sealing temperature control for packaging machines (2)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:03

- uso de algoritmos especiales (función de filtro con ajuste automático) integrados en el E5_D, diseñados específicamente para suprimir las variaciones de temperatura. El resultado es una mejor calidad de sellado en los envases.

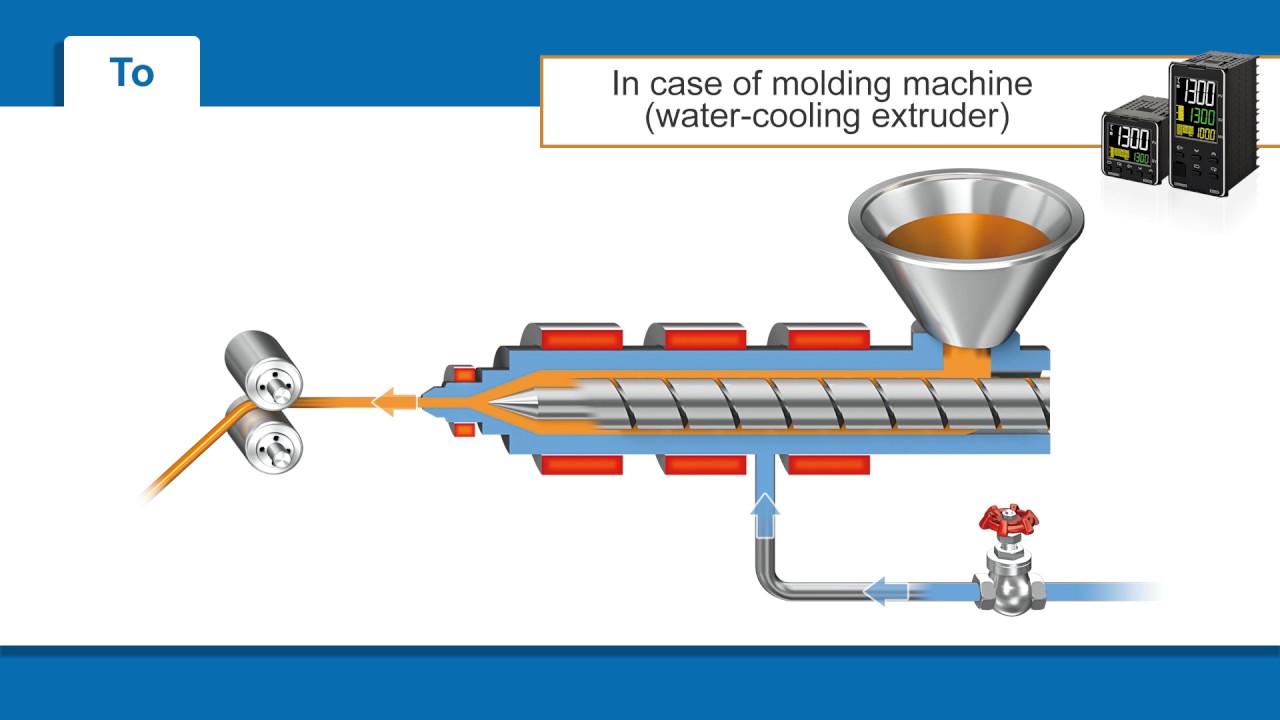

Ajuste de la salida de agua para refrigeración

-

E5_D TC: Temperature variations in molding machines minimized by a new algorithm

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality… With the E5_D, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

01:33

En una máquina de moldeo por extrusión con agua refrigerada, una mayor velocidad conlleva variaciones de temperatura debido a diversos factores, como la composición de los materiales o el agua de refrigeración... Para los operarios eso implica que tienen que realizar constantes ajustes en las válvulas para estabilizar la calidad final. Sin embargo, resulta muy difícil lograr una velocidad alta de producción al tiempo que se mantiene la calidad...

Con el E5_D, la función de ajuste de salida del agua de refrigeración reduce las variaciones de temperatura al mínimo, aumenta la capacidad de producción y mantiene una calidad constante.

Descargas

_cg_en.jpg)

Continúe e inicie sesión, o bien, regístrese al contenido de esta página

_cg_en.jpg)

Continúe e inicie sesión, o bien, regístrese al contenido de esta página